Project Name: Solar powered tobacco flue-cure chamber

Project Location: Zambia, Zimbabwe

Construction Unit: Ganzhou ETONE Foreign Economic & Technological Cooperation CO., LTD

Service Items: Design + Construction + Installation One-stop Service

The tobacco industry in Zambia is an important part of the national economy, and the contribution rate of tobacco to GDP reaches 3%. The tobacco industry directly or indirectly creates 450,000 jobs for the local people. Through our flue-cured tobacco technology, the advanced flue-cured tobacco technology was introduced into Zambia to solve the local tobacco processing problems. Tobacco processing export can not only solve the technical restriction problem of local flue-cured tobacco, but also greatly increase the farmers' income and the government's revenue after tobacco processing.

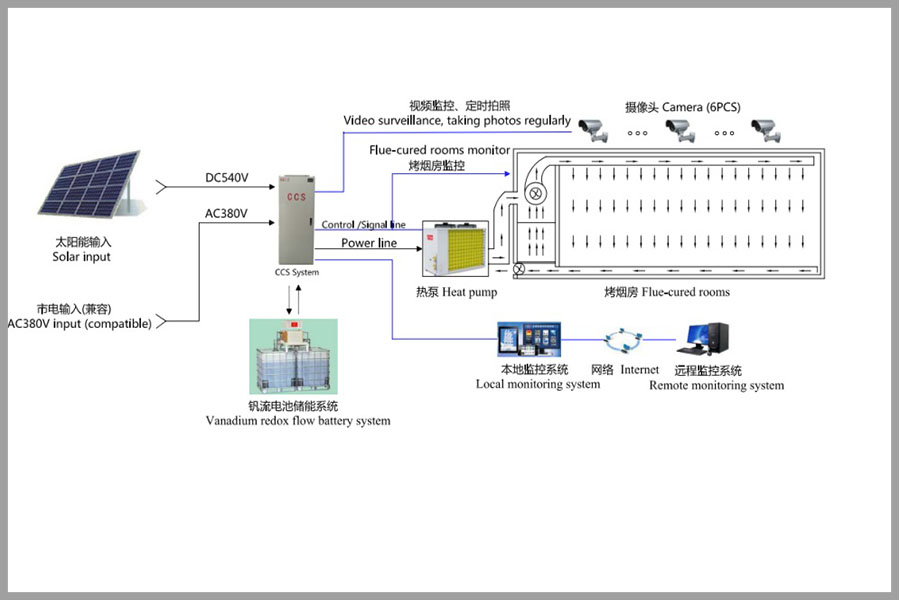

Energy-saving and efficient air source heat pump unit is used as heat supply system in solar powered automatic flue-cured tobacco house. The power supply system is completely powered by solar energy and compatible with the input of electricity, and the vanadium redox battery with a life of up to 20 years can be selected as the energy storage system to ensure the continuous and stable power supply in the flue-curing for 24 hours. To meet the construction needs of power-free areas and alleviate the shortage of local power supply.

According to the parameters of process setting, the flue-cured process of tobacco leaf is carried out automatically, the heat supply system is adjusted by frequency conversion, and the energy saving and consumption reduction is achieved. The flue-cured chamber system is equipped with video monitoring and remote monitoring client, image acquisition and storage, remote monitoring operation, to achieve all-round remote operation monitoring. It can be operated by a single flue-cured unit or designed into a cluster flue-cured chamber system with up to 50 flue-cured units, which can improve the utilization rate of heat energy, to realize remote integrated monitoring and management, and reduce the cost of labor input.

The technology of flue-cured tobacco chamber includes several important modules: solar energy utilization, CCS control system, high performance insulation material, energy storage system (Vanadium Redox Battery). Not only in the flue-cured tobacco chamber, for today's shortage of energy in Africa, it has achieved a milestone in the development of scientific research results that have been achieved or extended in the future.

1.Full solar power supply, compatible with the city electricity input, to meet the needs of the building in the area without electricity.

2.The vanadium redox battery with service life of up to 20 years is used as the battery energy storage system to ensure the continuous and stable power supply under the condition of solar power supply.

3.Heat pump unit is used as a heat supply system, with no waste gas, no waste water discharge, green environment.

4.It can be equipped with remote monitoring system, convenient for technicians in remote monitoring and management of flue-cured chamber.

5.With advanced waste heat recovery technology, unique heat cycle and air-sharing structure design. Higher heat efficiency, more uniform temperature.

Pic1:Demonstration site of solar powered tobacco flue-cure chamber

Pic2:Solar panels

Pic3:The process of flue-cured tobacco

Pic4:Customer investigation

Pic5:Group photo with customer

Pic6:Signing ceremony

Pic7:System structure diagram

【The last case】:No more 【The next case】:Solar powered flour milling plant